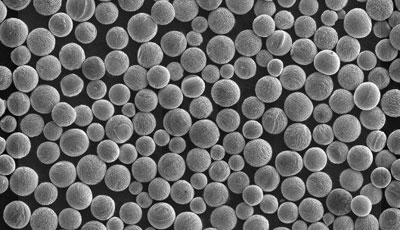

3d printing Sphericaltungsten powder is a kind of tungsten that has been created specifically to printing 3D. That dust is meticulously built to really make the form of a curved that’s why each dust compound being exceedingly homogeneous and little in ratios, allowing for outstanding printing results.

What’s tungsten dust?

Tungsten dust is an application of powdered metallic tungsten, employed as a brand new solution for the preparing of tungsten-processed ingredients such as for example alloys, tungsten products and. It is really a gray-black metal with a metallic Lustre (body-centred cubic crystal). Melting period 3400. Boiling factors 5555. The tungsten’s hardness is the most hard of the metals. The toughest tungsten post is 200250 and it is the toughest tungsten post that has been spun after the turning sort spins is 350400. It’s soluble within the mix p of nitric p as well as hydrofluoric acid. It touches in the mixture of sodium hydroxide and carbonate. A little soluble in nitric p and sulfuric p as well as aqua regia, insoluble in hydrofluoric p and water. potassium hydroxide. Tungsten has two forms A and B. At standard heat and atmospheric force, type A is really a solid circular style that is body-centered. Type T tungsten is able is found in the clear presence of oxygen. It’s secure to 630degC, and then turns to a tungsten at problems over 630degC. This technique is unreversible.

Huge difference between tungsten dust and curved tungsten dust

Tungsten dust and tungsten curved dust are generally dust kinds of tungsten, but they have apparent modifications in morphology, compound measurement and application.

Morphology

Tungsten dust is typically in granular selection, while curved tungsten dust is really a curved dust following certain processing. That curved shape allows tungsten dust to motion and load greater in purposes such as for example 3D printing, giving more standard printing results.

Substance Size

While tungsten grains have relatively big compound patterns, curved tungsten grains have really great compound patterns, typically in the nanometer range. That great compound measurement allows Circular Tungsten Powder to fit greater into the nozzle of the 3D printer, giving greater printing details. Simultaneously, the great particles may also be in a position to load the printing sleep, increasing the thickness and power of the produced part.

Applications

Tungsten dust carries a wide selection of purposes in many areas, such as for example lamp production, engineering, and bodily parts. In these purposes, tungsten dust is generally applied as an item or alloying element. Circular tungsten dust, on an added give, is quite well suited for places such as for example 3D printing, wherever it is ready of fabricating harder, high-precision elements and products since outstanding flowability, filling affect and printability.

How do you want to make tungsten dust?

It’s created by the hydrocarbon decrease on tungsten trioxide, or ammonium paratungstate. The task of creating the tungsten dust through hydrogen decrease could be divided into two phases one time in the original stage, at problems of 500-700degC, tungsten oxide is decreased to tungsten oxide; within the next period, at 700-900°D that period tungsten dioxide will soon be decreased to the tungsten powder. The decrease impact is usually done by the proper performance of a pipe or rotary furnace.

The potency of tungsten decreased dust (such as quality as well as compound measurement, agreement, measurement, etc.) largely depends in the manner of reduction. In the behave of lowering tungsten in a stove pipe, the principal factors that influence the rate of decrease are problems of decrease, amount of tungsten oxide into the burner vessel and the rate of activity that the vessel is in, as well as the rate of motion of hydrogen, and the quantity of water in hydrogen. While the problems of decrease, measurement of tungsten dust gets more coarse.

Manufacturing of tungsten dust coupled with method of hydrogen decrease, there’s also a tungsten oxide carbon decrease practices employed initially The decrease heat is a lot more than 1050 levels Celsius.The enjoy of the tungsten oxide dust that is built like that is poor. Additionally, with the utilization of calcium, aluminum zinc, and many decrease operates of tungsten oxide research is underway. For particular purposes that require ultra-fine, ultrapure compound measurement of tungsten dust the progress of the tungsten chloride hydrogen decrease method The tungsten dust compound measurement is less than 0.05mm.

Commercial production may be achieved through the reduction of tungsten trioxide by hydrogen, or ammonium partungstate is treated with p and then tungsten trioxide could be created by maturation decomposition and then decreased applying hydrogen.

Hydrogen decrease applying tungsten trioxide hydrogen decrease could be accomplished in two methods The initial stage is when tungsten trioxide heating to 550-800 , applying hydrogen reduction. Another stage of decrease takes place between 650 and 850 the tungsten dust is finished.

Also, it is possible to cut back ammonium paratungstate in to blue tungsten oxide (blue tungsten) originally by hydrogen, or, or even by hydrogen then decrease it back to tungsten by hydrogen. The measurement and material of the tungsten dust are a significant quality sign of the tungsten powder. The decrease method is done by way of a pipe or the rotary furnace.

Circular tungsten dust has the following advantages:

Circular shape: The curved shape allows the tungsten dust to higher load the printing sleep through the printing method, giving a far more standard printing result. Considered against normal granular tungsten dust, curved tungsten dust may greater adjust to the 3D printing brain and provide a simpler printing process.

Good compound measurement: The great compound measurement allows the tungsten dust to higher fit into the nozzle of the 3D printer, giving greater printing details. The great particles also load the printing sleep greater, increasing the thickness and power of the produced part.

Uniform compound circulation: Uniform compound circulation decreases clogging and imperfections through the printing method and improves printing success. In normal granular tungsten grains, the compound circulation is typically perhaps not standard enough, which can result in clogging or imperfections through the printing process. The standard compound circulation of curved tungsten dust may simply handle this problem.

Large enjoy: High-purity tungsten dust provides greater printing efficiency and bigger printing quality. In a few purposes, it is required to utilize high-purity solution for printing to ensure the quality and efficiency of parts.

Circular Tungsten Powder Plan Places

Circular tungsten dust carries a wide selection of purposes, including while not limited to the following places:

Aerospace: Circular tungsten dust works extremely well to create high-performance elements such as for example plane structural components and engine parts. In these purposes, the large power, large thickness and large enjoy options that come with tungsten dust provides greater printing efficiency and quality.

Automotive industry: Circular tungsten is useful for the production of elements for automobiles, including figure elements, engine components and various parts. The solid longevity and opposition to heat of tungsten dust may increase printing quality and performance.

Medical topic Circular tungsten works extremely well to generate medical products like dental implants, medical units and others. The large biocompatibility as well as the large power of tungsten dust can increase printing quality and printing performance.

Structure: Circular tungsten dust works extremely well to create architectural models and components. The large power and wear-resistant houses of tungsten dust provides greater printing efficiency and quality.

Technology: Circular tungsten dust works extremely well to create electronics, such as for example semiconductor products, signal cells and therefore on. The large thermal and electric conductivity of tungsten dust provides greater printing efficiency and quality.

It ought to be seen that applying curved tungsten dust for 3D printing requires a certain amount of skill and experience. If you’re a newcomer, it is preferred to apply with even more accessible 3D printing products first. Simultaneously, applying tungsten dust for 3D printing also requires certain focus on safety, as tungsten is really a high-density metal that’ll simply trigger damage to the person body. When this, be sure to follow the applicable safety regulations and operating procedures.