Aluminum casting is both an art and a science. It combines craftsmanship with metallurgy to create precision-engineered components used in various industries, from aerospace to automotive. To master the craft of aluminum casting, one needs a deep understanding of the process, materials, and techniques involved. In this blog, we’ll explore some valuable tips and techniques that can help you achieve excellence in A356 Aluminum Casting.

1. Understand the Aluminum Alloys

The first step in mastering aluminum casting is to familiarize yourself with the different aluminum alloys available. Each alloy has unique properties, including strength, corrosion resistance, and heat conductivity. Choose the alloy that best suits your project’s requirements. Common aluminum casting alloys include A356, 6061, and 7075.

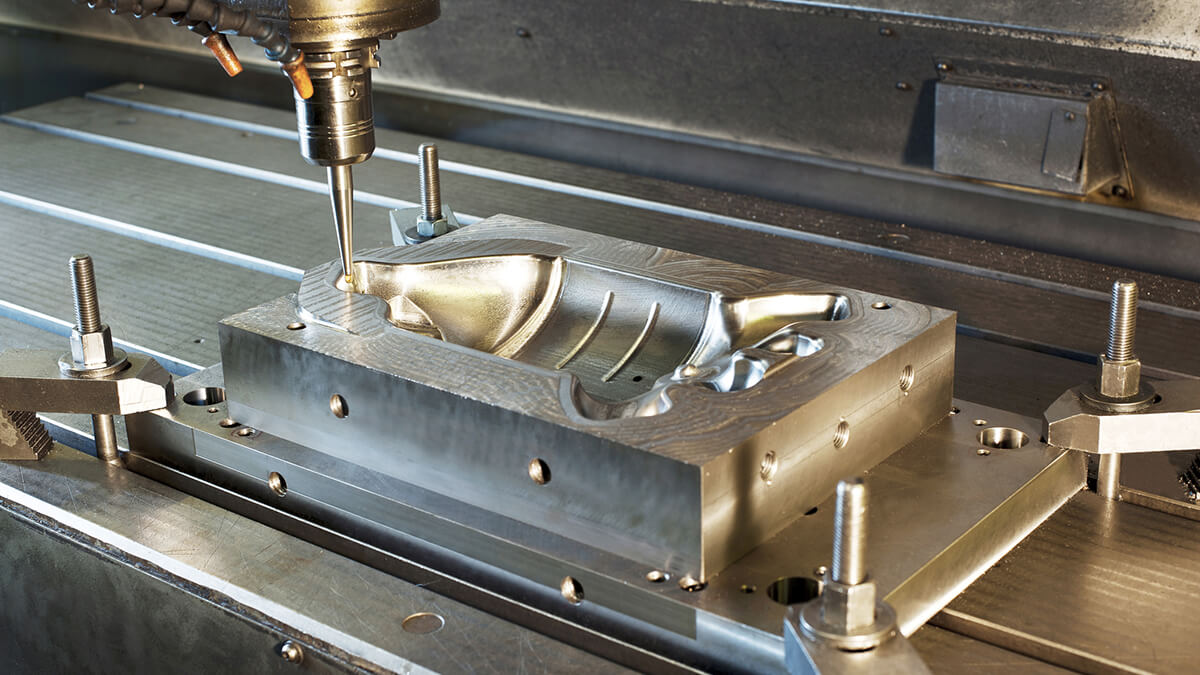

2. Perfect Your Pattern Design

The pattern is the blueprint for your casting, and its design is crucial. Pay attention to draft angles, fillets, and parting lines to ensure smooth mold release. Pattern materials, such as wood, plastic, or metal, should be chosen with care, considering factors like durability and ease of machining.

3. Optimize the Mold

The quality of your mold significantly influences the final casting. Use high-quality sand or other mold materials and ensure proper compaction to avoid defects like sand inclusions or porosity. Implementing effective gating and risering systems is crucial for achieving even filling and reducing the risk of shrinkage defects.

4. Control Pouring and Cooling

Proper temperature control during pouring and cooling is paramount. The pouring temperature should be within the recommended range for your alloy to prevent issues like incomplete filling or hot tearing. Monitor and control the cooling rate to ensure uniform solidification and minimize the risk of cracking.

5. Implement Quality Control

Quality control is an ongoing process throughout aluminum casting. Regularly inspect molds, cores, and castings for defects, such as surface imperfections, cracks, or inclusions. Implement non-destructive testing methods like X-ray or ultrasound to detect internal flaws. Comprehensive inspection ensures that only high-quality castings make it to the final product.

6. Practice Proper Safety Protocols

Safety should always be a top priority in aluminum casting. Molten aluminum is extremely hot and poses significant hazards. Wear appropriate protective gear, such as heat-resistant clothing, gloves, and face shields. Maintain a clean and organized workspace to reduce the risk of accidents.

7. Master the Art of Melting and Pouring

Achieving the correct melt temperature and pouring technique is critical. Use high-quality crucibles and ensure the melt is free of impurities. When pouring, maintain a steady and controlled stream to prevent turbulence, which can introduce air and lead to defects.

8. Consider Heat Treatment

Heat treatment can enhance the mechanical properties of aluminum castings. Familiarize yourself with the heat treatment requirements for your specific alloy and casting application. Proper heat treatment can improve strength, hardness, and dimensional stability.

9. Invest in Education and Training

The world of aluminum casting is continually evolving. Invest in education and training to stay updated on the latest techniques, technologies, and best practices. Industry workshops, seminars, and online resources can provide valuable insights and skills.

10. Embrace Innovation

Aluminum casting is not static; it’s a field that continues to evolve. Stay open to innovative technologies like 3D printing for molds, real-time process monitoring, and advanced simulation software that can help optimize your casting process.

Conclusion

Mastering the craft of aluminum casting is a journey that requires dedication, continuous learning, and attention to detail. By understanding the nuances of aluminum alloys, perfecting your pattern design, optimizing molds, practicing safety protocols, and staying open to innovation, you can elevate your aluminum casting skills to create high-quality, precision components that meet or exceed industry standards. Whether you’re a seasoned professional or just starting, the pursuit of excellence in aluminum casting is a rewarding endeavor that can lead to the creation of exceptional products for various industries.